Trailers

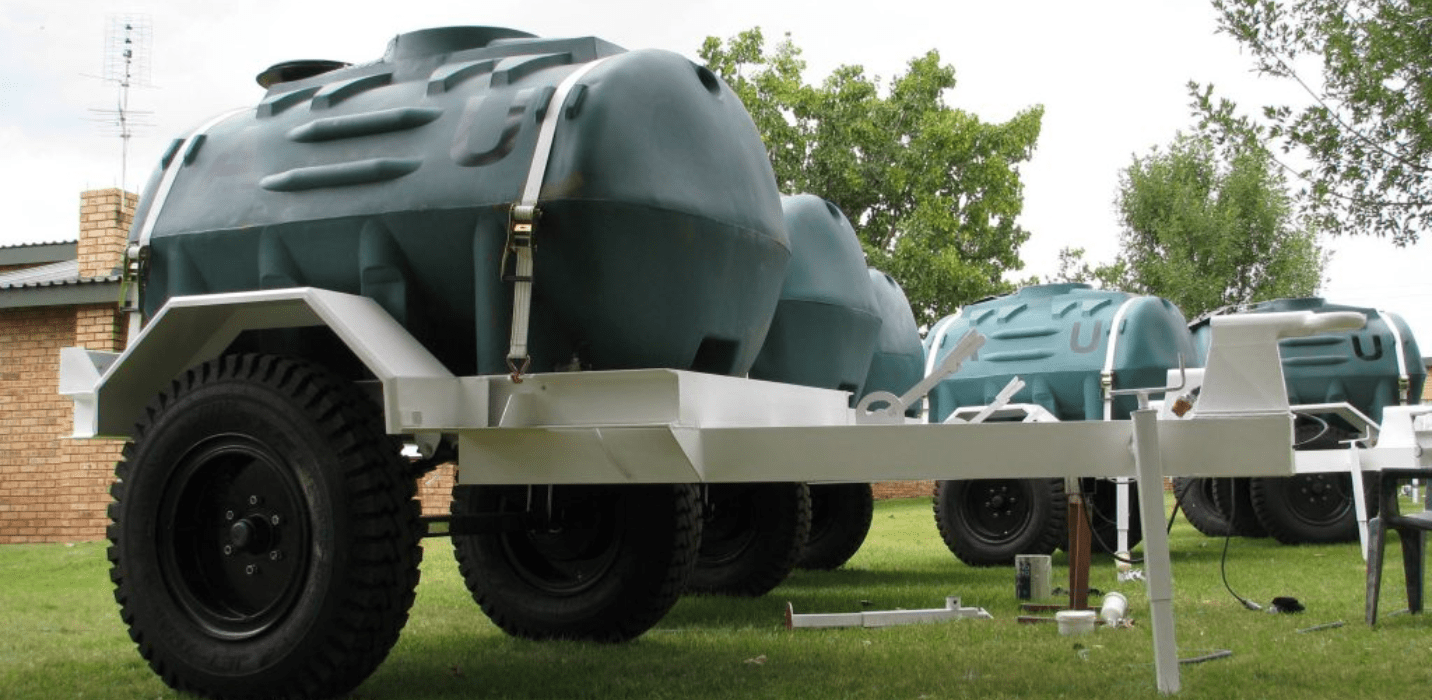

Osprea Logistics’ bespoke cargo, water, fuel, and specialty trailers and bowsers are engineered and designed to military standards for use in the world’s most inhospitable and austere off-road environments.

Incorporating only the heaviest and durable components, no Osprea Logistics trailer has experienced a break-down failure in almost 15 years of in-field use with African militaries, fire-fighting, peacekeeping, and mining projects.

These trailers can be customised to meet any client requirement of size, utility, and configuration.

All Osprea trailers are engineered using heavy tubular steel design and exceed all current military standards for light trailer component strength and carrying capacity.

Osprea water trailers use heavy-duty polyethylene with a minimum wall thickness of 10mm minimum. This material is recommended by Health Ministries in Europe and the US for human potable water usage, and is.proven to have lower microbiological and bacterial production levels versus standard steel tanks. With zero corrosion and UV light impact, Osprea’s polyethylene tanks have long lives and are easily heat welded if damaged by impact. Plumbing include 4 water access points (lockable valves).

In addition to stock trailers up to 2T or 3,000L, Osprea designs and builds up to 5,000L and 10,000L detachable bowser units for fuel and water, which can be built into a cradle or onto a lighter frame, making them easily removable from a vehicle by forklift. These detachable bowser units free up base vehicles for other operations when not needed as operational tanker units, and allows for the bowser units to be positioned free-standing on the ground as remote fuel or water positions. Equipped with 600L per minute pumps and all hoses, these “Slip On Bowsers” are an ideal operational addition due to their versatility.

Frame: Channel (100 x 50)

Solid Beam Axle Capacity: 1.8 ton Heavy Duty Jockey Wheel

Spring: Semi-Elliptical 10 leaf

Parking brake: Hand brake Heavy duty jockey stand

Tyres: 750×16″

Rims: 16″

Cargo Bed: Dropside only to the rear

Load Space Height: 400mm

Overall length: 3.287m

Overall width: 1.785m

Overall height: 1.3m

Trailer weight: approx 550 kg

Maximum load: 1450kg

Frame: Heavy gauge steel structure (100 x 50 channels frame) larger sections used on tow bar

Solid Beam Axle Capacity: 60mm tubular 4 ton

Spring: Semi-Elliptical 8 leaf spring pack per side

Parking brake: Hand brake heavy duty jockey stand

Tyres: 750×16″

Rims: 16

Cargo Bed: Floor constructed from 2mm lip channel as opposed to standard sheet. All round cargo bin from 2mm steel

Load Space Height: 400mm

Overall length: 4.62m

Overall width: 2.4m

Overall height: 1.7m

Trailer weight: approx 1000 kg

Maximum load: ±3000kg

Frame: Heavy gauge steel structure (100 x 50 channels frame) larger sections used on tow bar

Solid Beam Axle Capacity: 60mm tubular 1.8 ton

Spring: Semi-Elliptical 8 leaf spring pack per side

Parking brake: Semi-Elliptical 8 leaf spring pack per side

Tyres: 750×16″

Rims: 16″

Tank Capacity: 1,000L

Composition: Polyethylene. Heavy duty wall thickness (ave. 10mm)

Plumbing: 4 water access points lockable valves

Overall length: 3.3m

Overall width: 1.8m

Overall height: 1.3m

Trailer weight: approx 520 kg

Maximum Payload: 2000kg

Frame: Heavy gauge steel structure (100 x 50 channels frame) larger sections used on tow bar

Solid Beam Axle Capacity: 60mm tubular 1.8 ton

Spring: Semi-Elliptical 8 leaf spring pack per side

Parking brake: Semi-Elliptical 8 leaf spring pack per side

Tyres: 750×16″

Rims: 16″

Tank Capacity: 2,500L

Composition: Polyethylene. Heavy duty wall thickness (ave. 10mm)

Plumbing: 4 water access points lockable valves

Overall length: 4.62m

Overall width: 2.4m

Overall height: 2.0m

Trailer weight: approx 750 kg

Maximum Payload: 3250kg

1x 5000L tank

Length: 3.1m

Width: 2.48m

Height: 1.589m

Above Options available on frames per upper drawings on in heavy duty cradle, per bottom right and below, allowing units to moved, loaded and unloaded while full.

2 x 5000L Extra Heavy Duty Horizontal Tanks

Length: 5.015m

Width: 2.5m

Height: 1.6m

Above Options available on frames per upper drawings on in heavy duty cradle, per bottom right and below, allowing units to moved, loaded and unloaded while full.