24 Mar THE DO’S AND DON’TS OF USING AN ARMORED VEHICLE:

In the world of military operations, high-security missions, and high-risk environments, the role of an armored vehicle (AV) is undeniably critical. Whether it’s for defense, transport, or tactical operations, the reliability and performance of an AV can mean the difference between mission success and costly failure. However, like any specialized equipment, armored vehicles require the right handling, maintenance, and attention to detail to function at their best. At Osprea, we understand the importance of proper usage and care for vehicles that operate under extreme conditions. Here’s your guide to getting the most out of your armored vehicle.

Maintaining Peak Performance: What You Need to Know About Your AV

Armored vehicles aren’t your average ride. With reinforced structures designed to protect against ballistic and blast threats, they require a higher level of care and specialized servicing compared to standard military or civilian vehicles. Ensuring the integrity of crucial components like armor plating, ballistic glass, run-flat tires, and mechanical systems can prevent failures in the field—keeping you mission-ready.

How Often Should You Maintain Your AV?

The maintenance frequency for your armored vehicle depends on its usage and environment. To ensure long-term reliability, the following schedule should be adhered to:

- Daily Inspections: A quick check of fluid levels, tire condition and structural integrity before deployment ensures everything is in order.

- Weekly Maintenance: Conducting detailed diagnostics on braking, suspension, and communication systems can catch any developing issues early.

- Monthly Servicing: Comprehensive inspections of armor plating, engine performance, and electronic systems are vital for long-term functionality.

- Post-Mission Checks: After each mission, inspect the vehicle for damage from ballistic impacts, rough terrain, or extended use. Immediate repairs should be prioritized to maintain readiness.

Best Practices: The Do’s of Using Your Armored Vehicle

Maximizing your armored vehicle’s effectiveness starts with following a few best practices. Here are the key do’s every operator should follow:

- Follow Manufacturer Guidelines: Always adhere to the vehicle’s manual, recommended operating procedures, and maintenance schedules.

- Train Your Personnel Thoroughly: Ensure that all drivers and crew members are well-trained in the specific handling of armored vehicles under different conditions.

- Monitor Weight Distribution: Avoid overloading the vehicle. Excessive weight can negatively impact maneuverability and diminish the protective capabilities of the armor.

- Conduct Regular Armor Inspections: The armor plating, ballistic glass, and blast-resistant features should be checked regularly for wear and tear to ensure they’re functioning at peak levels.

- Stay Situationally Aware: Armored vehicles offer enhanced protection, but vigilance is key. Always be aware of your surroundings and avoid unnecessary threats.

What to Avoid: The Don’ts of Operating Your AV

While armored vehicles are built to handle extreme conditions, improper use can still lead to costly mistakes or risks. Here’s what you should avoid:

- Ignoring Warning Indicators: Pay close attention to dashboard alerts, unusual noises, or warning lights. These could indicate issues that need immediate attention.

- Skipping Routine Maintenance Checks: Failing to keep up with regular inspections can lead to unexpected breakdowns that compromise operational readiness.

- Overloading the Vehicle: Don’t exceed the vehicle’s weight capacity. Overloading can negatively affect mobility, speed, and the vehicle’s armor protection.

- Neglecting Tire Maintenance: Run-flat tires are a key component of an armored vehicle’s mobility. Regular checks ensure they’re up to the task, especially in extreme environments.

- Relying Solely on Armor: While AVs provide excellent protection, they are not invincible. Always combine the vehicle’s armor with effective tactical movement and situational awareness.

Ensuring Mission Success with Osprea

By adhering to these maintenance practices and operational guidelines, operators can ensure that their armored vehicle remains a reliable and effective asset in any mission.

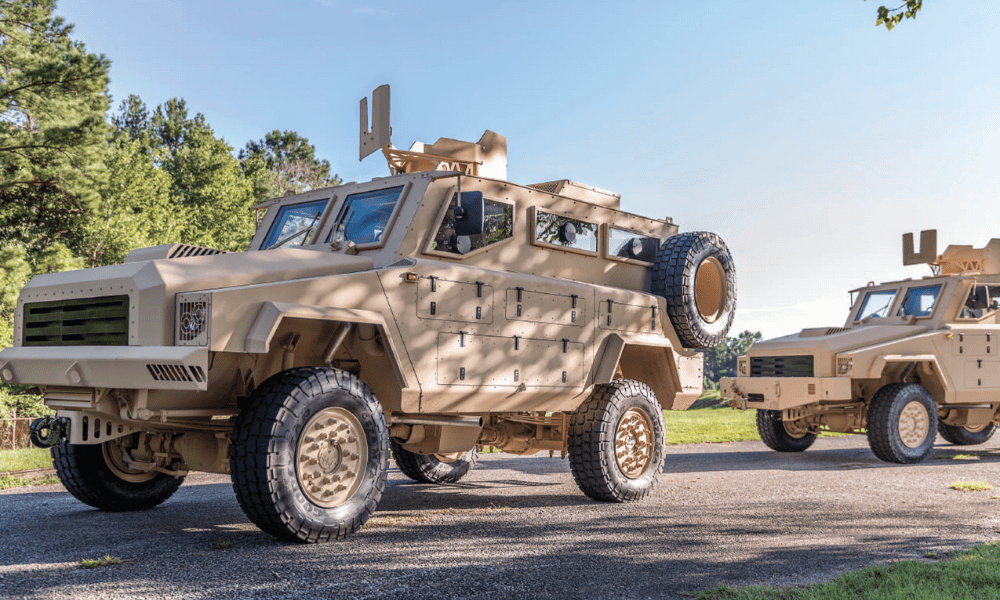

At Osprea, our commitment to innovation and quality means that our Mamba™ MRAPs are built to withstand even the most challenging environments. With careful attention and routine care, your armored vehicle will continue to provide the highest level of protection, allowing you to focus on what matters most—mission success.